Hello, RPV.

This time, it was held at the Kumamoto Works of Honda Motor Co.

I went to an event called Motorcycle Homecoming.

From early in the morning, many people from inside and outside of the prefecture came to the event.

Last year the event was cancelled due to bad weather.

It was pouring early in the morning, but we are glad that it managed to recover.

The highlight of the event will be the visit of Mr. Freddie Spencer!

I was not scheduled to participate in the opening, but I was rushed out of the opening.

He was also a participant in the event. The audience was very excited by his fan service.

Here's a thumbs up for the visitors' Spencer replica helmets.

At the talk show

She had a mild-mannered atmosphere from her youth, but she rounded out and

It looks even gentler!

This is the expression on the face of the Daytona Racer engine startup with so much exhaust noise.

I guess I was used to hearing that when I was an active racer!

He was series champion in both the 500cc and 250cc classes of the WGP in 1985.

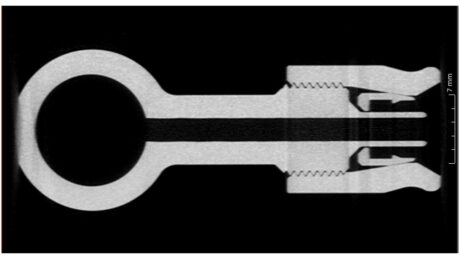

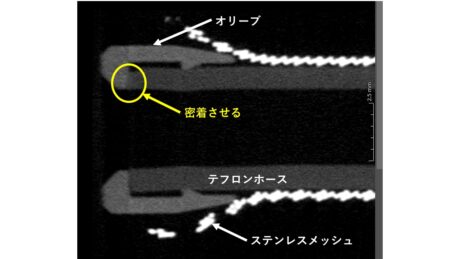

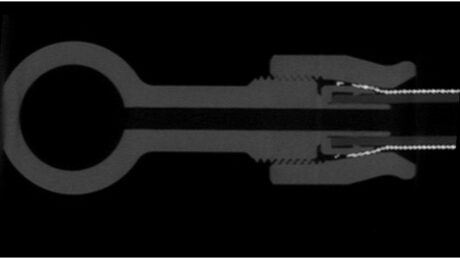

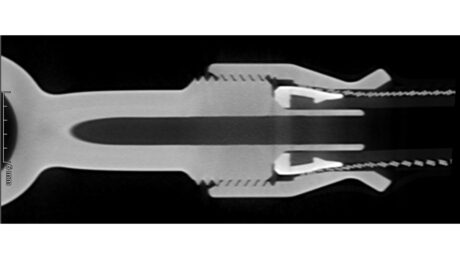

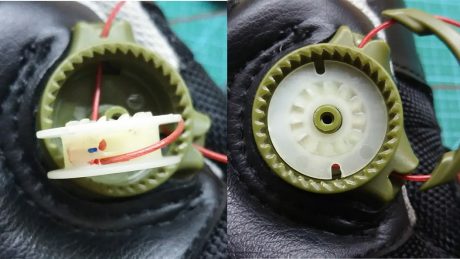

The photo below is the car he was driving at the time. The photo below is the car he was driving at that time.

Then there is the new CB1000F model that is being talked about.

I am glad to hear that Mr. Freddie Spencer is doing well.

See you soon~!