Hello, RPV.

Well, this earthquake was amazing. The past few days have been tough with cleaning up around the house and outside.

We would like to take this opportunity to again thank those who have expressed their sympathy and encouragement.

Well, as soon as possible, I went fishing in Amakusa before the earthquake.

We caught about 30 horse mackerels about 20 cm in length.

The best sashimi is freshly caught fish. Well, whatever the case, if you are going to eat it, you will have to dismantle the fish. So, what you need is a knife. Recently, stainless steel knives, which are rust-resistant and clean, have become the mainstream, but I use a handmade Japanese kitchen knife forged from iron. The image below is a handmade small knife made by a knife shop (blacksmith shop) in Kumamoto.

I am not familiar with the process of making interrupted Japanese knives, but it is said that they are forged by interrupting a hard metal (which is also iron) that will become the blade into the iron material that will be the base of the knife. I think the quality of the work is determined by how the different metals (though they are the same iron) are joined together by heat and pressure.

So I was curious to see if I could scan it with an X-ray CT scanner to check the internal condition. It will be interesting to see if the metals are distinguishable from each other in the work. I expect that it would be difficult to tell them apart because they are made of the same material, iron, and the amount of X-rays transmitted through them is about the same. It will also be interesting to see how well the metals are bonded (adhered?) to each other. It will be interesting to see how well the metals are bonded (adhered?) to each other.

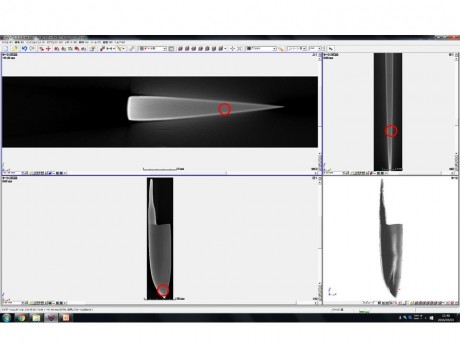

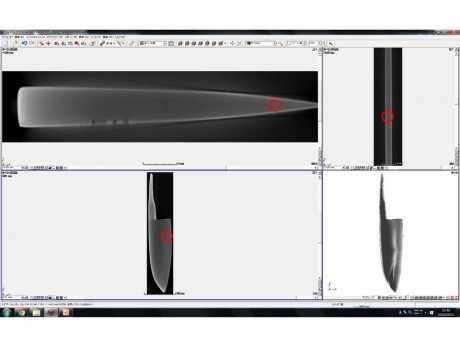

In the image below, the top and bottom left images and the top right image are cross-sectional images, and the bottom right is a 3D image. The red circles are linked from three different directions and magnification rates have been changed to make them easier to see. The images are still the same steel, so no differences can be detected.

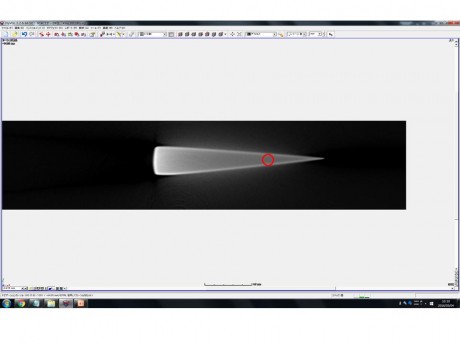

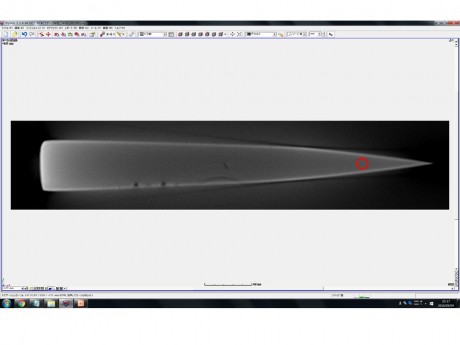

This is the upper left magnified cross-sectional image of the above image.

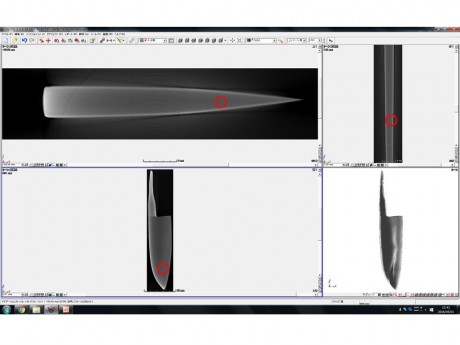

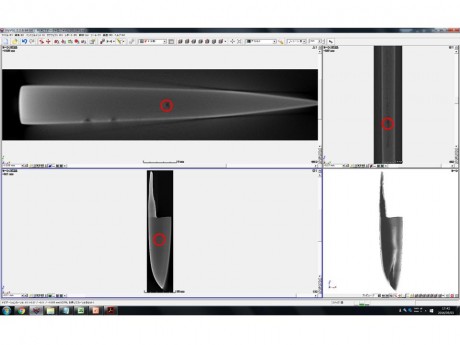

Next is a little more toward the middle from the tip. Similarly, there is no particular change.

Next is a little behind the middle. There is nothing special here either.

The last one is in the middle of the knife. An elongated void can be seen. This is an authentic interrupted knife, so the joint in this area must be tight. Well, the existence of this void is the proof of authentic interrupted forged Japanese kitchen knives. The blade, which determines the sharpness of the knife, was beautifully jointed in every part. As I said, handmade kitchen knives by Japanese blacksmiths are wonderful.

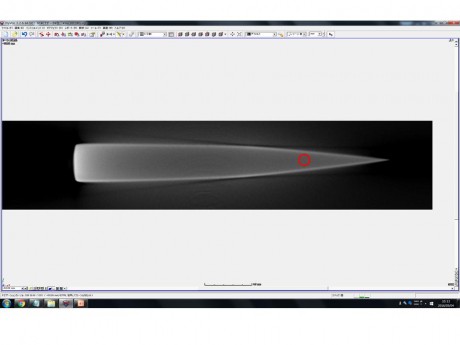

This is an enlarged cross-sectional image of the upper right of the image above. A small gap exists, perhaps to allow the blade to break in.

As a conclusion, as expected, we could not distinguish between the different types of steel, which was the most important thing to know, and the important joints of the knife were confirmed to be perfectly joined all along the blade without any defects. The X-ray CT scanner was able to detect voids around the center of the knife, which are inevitably present because metal is broken into metal in the production of knives.

If you are unable to predict whether or not an X-ray CT scan can be used for observation in this way, we would be happy to provide you with our free sample imaging. Although we can only provide you with one or two cross-sectional images, we think it will help you decide whether or not to request the service.

Japanese knives have excellent sharpness and rust can be prevented with simple maintenance, and if they are sharpened with a whetstone, their sharpness will be restored. Stainless steel knives are made of hard material, so it is said that it is difficult to sharpen them with a whetstone.

Of course, I used this Japanese knife to cut the horse mackerel into sashimi and fry it, and it was delicious. The quality of this knife is impeccable and will continue to serve me in my kitchen for many years to come.

*The enlarged image was created additionally later, so its position is slightly different from that of the quadripartite image.